The Common Types of V-Belts: The Structure and Sizes of Belts

Power Transmission is the most crucial factor ever in engineering and people’s everyday life. We use power transmission devices (belts, chains, gears) to transfer power from one shaft to another․

In this article, we will introduce you to one of the most common types of power transmission devices, known as V-belts. V-belts get their name from their trapezoidal shape․ This design allowed the belt to wedge tightly into the sheave groove as tension was applied to the belt, and higher torque values and higher drive speeds could be maintained with less slip. Now let’s check the structure of industrial V-belts.

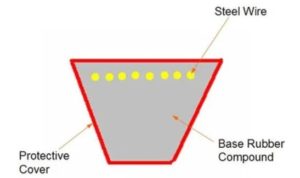

V-Belt Structure

V-belt consists of steel wires, a base rubber compound and protective cover. Steel wires provide the necessary reinforcement and strength to the V-Belt for transmission of the torque. The wires are surrounded by a special rubber compound providing shape to the V-belt. The protective cover is against the high temperature generated during the movement of the V-belt.

V-Belt Types and Sizes

As a distributor of various belt manufacturers, HVH Industrial Solutions introduces the common types of V-belts. They are available in six classes – Classical V-belts (ranked by their dimensions from A to E), Narrow V-belts (ranked by their sizes 3V, 5V, 8V), light duty Fractional Horsepower belts (ranked by their sizes 2L, 3L, 4L, 5L), Metric V-belts (classified by their dimensions SPA, SPB, SPC, SPZ), V-Ribbed belts (ranked by their dimensions J, L, M, K) and Variable Speed V-belts (ranked by their dimensions V).

Classical V-Belts

Classical or Conventional V-belts are the most practical, economical, and constant V-belts for most industrial drives. They have an outer fabric wrap treated with an engineered synthetic rubber compound that is exceptionally resistant to oil and heat, specifically designed for excellent wear resistance. The V-belt standard design allows them to be used for applications ranging from light-duty power transmission to heavy-duty machines. They are suitable for printing machines, machine tools, crushers, etc.

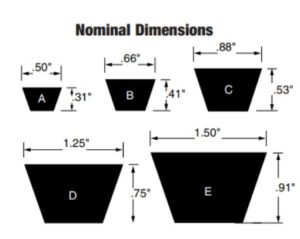

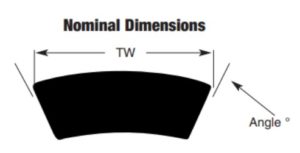

The part number format of classical V-belts is structured with the help of cross-section size and inside length in inches (e.g., A20, A – cross-section, 20 – inside length in inches). The nominal dimensions generally used in the US are described in the picture below.

Classical Cogged V-Belts

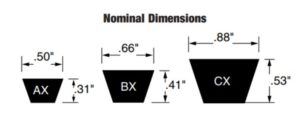

Classical Cogged V-belts are high horsepower energy savers with a molded cog design. They are heat and oil-resistant products widely used for agricultural machinery, escalators, dynamos, blowers, etc. The classical cogged V-belts are classified by the letter “X” (e.g., AX15). The nominal dimensions generally used in the US are described in the picture below.

Classical Combo V-Belts

Classical Combo V-belts are used for high shock load and pulsating drives where extra stability is beneficial. The tie band assures lateral rigidity and guides the belts into the sheave grooves. They are ideal for use on vertical shaft drives.

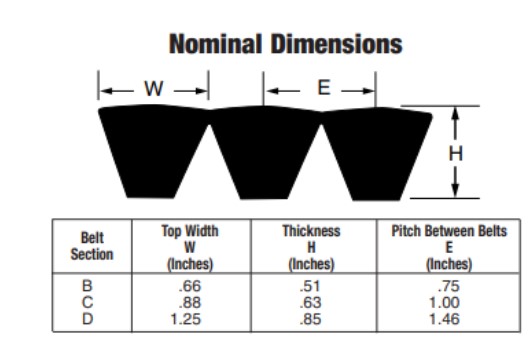

The part number of Combos is structured in the following format: e.g., 2B52, (2 – the number of ribs, B – cross-section, 52 – the belt inside length in inches․ The nominal dimensions generally used in the US are described in the picture below.

Narrow V-Belts

Narrow V-belts transmit power more efficiently, delivering higher horsepower ratings. This is their advantage over Classical V-belts. They are suitable for drives with high belt speed due to their compact size. The belts are ideal for crushers, freezer, large pumps, machine tools, etc.

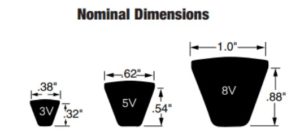

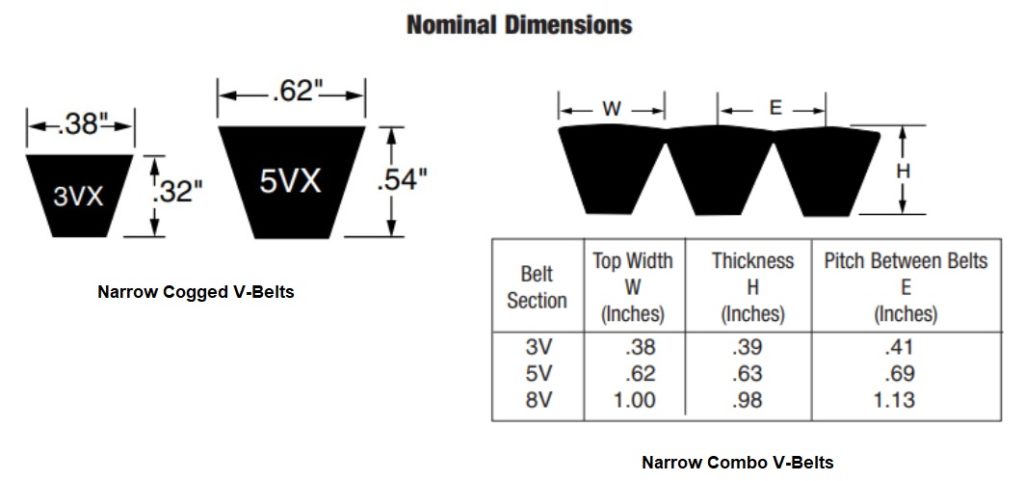

The part number format comes with belt top width and nominal outside length in inches: 5V250, 5V ((⅝”) – top width, 250.0 -outside length). The nominal dimensions generally used in the US are described in the picture below.

Similar to Classical V-belts, Narrow V-belts also come with Narrow Cogged and Narrow Combo versions. Accordingly, with the same principle, the Cogged is classified by the letter “X” 3VX and, 5VX (e.g., 3VX15). The Combos are structured in the following format: 2/3V150. The nominal dimensions generally used in the US are described in the picture below.

Fractional Horsepower Belts

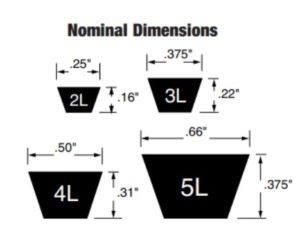

Fractional Horsepower (FHP) belts are designed for light-duty purposes and shorter center distance drives. The typical applications include domestic washing machines, garage equipment, small fans, and refrigerators. They will never be used on any heavy-duty applications, even if they seem to fit the classical or narrow V-belt pulley grooves.

The part number is structured similar to wedge: 2L, 3L, 4L and 5L (e.g., 3L260, 3L ( ⅜”) – top width, 26.0 – outside length). The nominal dimensions of the FHP belts that are generally used in the US are described in the picture below.

Metric V-Belts

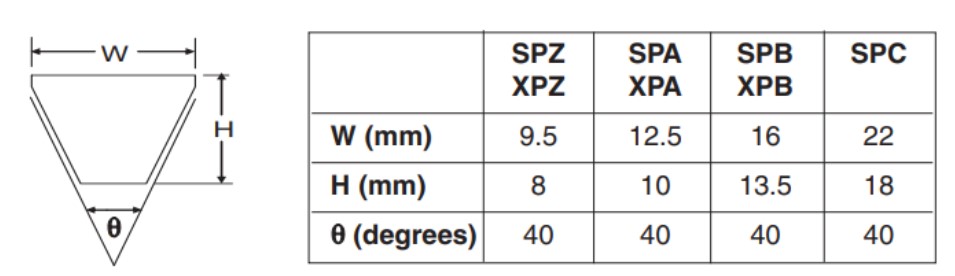

Metric V-belts are European standard belts based on a metric measurement system and different cross-section designations. These are considered the replacement belts for Narrow belts used in industrial applications like machine tools, textile mills, and food processing plants.

Metric V-belts are available in SPA, SPB, SPC and SPZ classes and their cogged versions. For example, SPA900 (SPA – cross-section, 900 – nominal outside length in meters). The Cogged is classified by the letter “X, as the other belts, mentioned above, XPA, XPB, and XPZ (e.g., XPZ612). Nominal dimensions are described in the picture below.

V-Ribbed Belts

V-Ribbed belts are relatively thin and flexible products made of abrasion-resistant material. The belts’ low mass and high flexibility allow them to tolerate small sheaves, reverse bending, high linear speed, and high speed ratios. They have the versatility to handle heavy, high-speed industrial applications such as machine tools and light-duty, slower applications such as exercise equipment. The belts provide smooth, vibration-free, and clean operation.

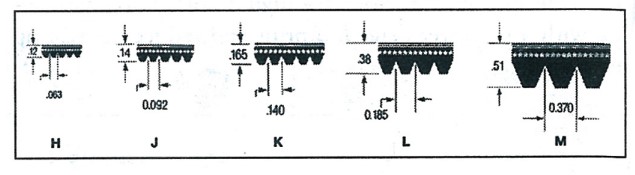

They are classified by H, J, K, L and M profiles (e.g., 310J4, 310 – nominal outside length in inches, J – cross-section, 4 – a height in meters). Nominal dimensions are described in the picture below.

Variable Speed Belts

They are a particular class of two-sheave belts that can differ from the driven sheave speed. They can be found in either envelope or raw edge constructions. Due to their broader and thinner structure, variable speed belts have more unsupported cords concerning the pulley sides than classical or wedge v-belts.

The standard part number is structured in the following format: e.g.,1228V255 (12 – top width, 28 – included angle, V=Variable Speed, 255=25.5” – pitch length. Nominal dimensions are described in the picture below.

V-belts are maybe the most applicable power transmission products used in a wide range of applications and industries worldwide. They are relatively economical to install and maintain; they have a simple design and easy installation procedure, and they do not require lubrication. When speaking about V-belts, it is essential to mention the tensioning. Correct V-belt tensioning is the number one vital factor for long, efficient and safe operation. Deficient tension can cause slippage, excess heat, and premature belt & pulley wear. Redundant tension results in excessive stress on belts, bearings, and shafts. Thus, to get the most from your belt drive, pay proper attention to the V-belt tensioning and pulley size.